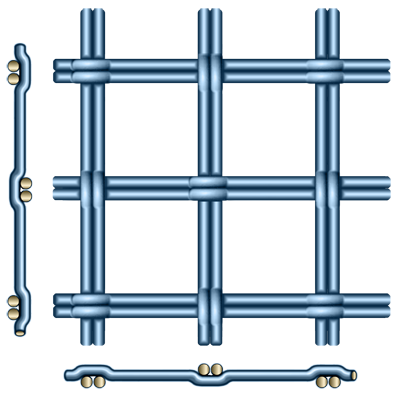

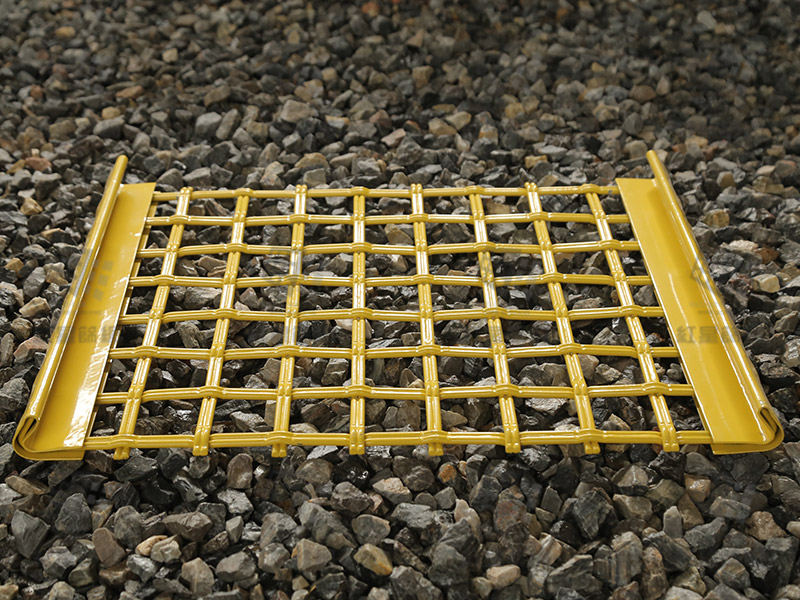

TwinWire Woven Wire Mesh is tougher solution for high-impact applications, could bring extra muscle from your woven wire.

Constructed of two side-by-side, lighter-gauge woven wires, it withstands up to 4 times more impact force than heavier single-strand woven wire. As a result, TwinWire Woven Wire Mesh has become standard on many scalping screens and top decks where material impact tends to break even the heaviest wire gauges. TwinWire Woven Wire Mesh also delivers more material throughput than perforated punch plate and costs less.

The Benefits Are Clear

-- Handles high-impact loads & wears better than heavier single-strand wire

-- Excels with large feed materials

-- Reduces screen cloth change-outs & production costs per ton

-- Improves material throughput by up to 50% with more open area than perforated punch plate

-- Increases the volume of material you can process

-- Reduces installation time because the two lighter-weight wires bend easier than one heavy wire

• Durable double woven wire design handles heavy impact, while extending wear life and minimizing change-outs.

• Double weave provides a greater open area than polyurethane or perforated plate.

• Cost effective design provides a viable alternative to more expensive polyurethane perforated plates.