Flip-Flow Vibrating Screens remove fines out of wet, sticky or generally difficult to handle materials. Materials processed using a Flip-Flow Vibrating Screen typically cannot be screened using other technologies, such as rotary screens, conventional vibrating screens, etc. Applications where the screen might be used include municipal solid waste, tire recycling, construction & demolition waste, glass recycling, biomass, metals, food recycling, drug recycling, used car recycling, slags from incineration, oil and sludge, etc.

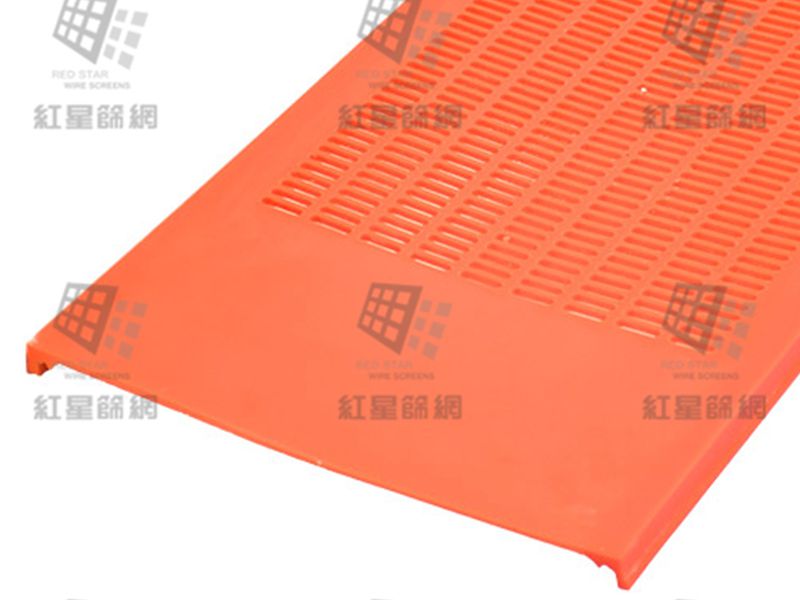

Screens are made of high density polyurethane panels. Each panel is fixed to both the main frame and the sub-resonant frame. By amplifying the vibration of the main frame of the screen in the sub-resonant frame and due to the polyurethane panels being fixed to both frames, screen panels bump together creating the "flip-flow" motion. This ensures that screened material will not stick or get caught in the screen.

BENEFITS

Non blinding screening mats – less contamination

Compact and modular construction

Single- or multi-deck execution

Dynamic wear resistant screening mats allow an effi cient

material flow – screwless mounted (fast changeover).

The high acceleration on the screening mats ensures a

self-cleaning effect.

Infinite adjustment of the vibrating parameters to match

changing product characteristics / qualities

Low operating and maintenance costs