Various shapes.

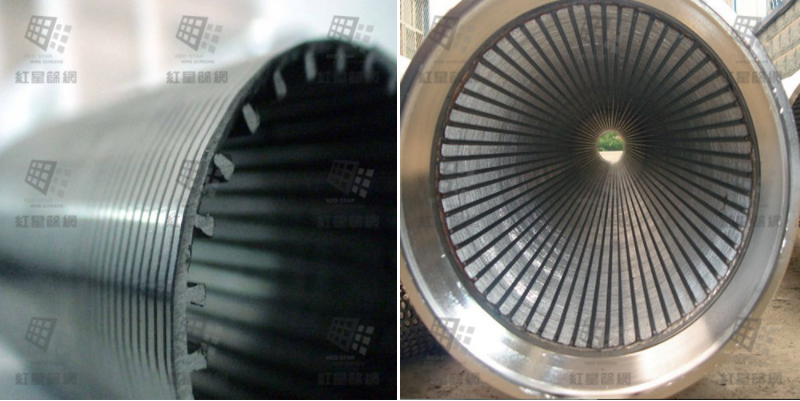

They have flat type, cylinder type, basket type and slope type according to the screen type. Aslo called flat welded screen panel, cylinder wedge screen and sieve bend screen. They are aslo called woven wedge wire and welded wedge wire according to the weaving type, such as crimped wedge wire, welded wedge screen panels.

Various applications

Wedge wire screen is the most commonly using screen for filtration and separation in liquid/gas, water wasting, mining, food and so on. Our wedge wire flat screen panels are used on vibratory screens for dewatering, draining and desliming in Mining Industry. Applications for wedge wire screen panels include cross flow sieves, vibrating screen decking,mineral processing, surface water intake screens, fish diversion screen panels, hatchery screens, food processing, and flooring for malt kiln, germination, and grain drying.

Wedge wire screen has a wide range of applications in lots of fields. They can be used as vibrating screen panels, floors, and decorative material. They have more applications in mine, coal, chemical, food and water treatment applications for filtering, screening and sizing. The different shapes and types of wedge wire screen can suit more machines, including carbon filters, desulfurizers, molecular sieves, gas sweeteners and lauter tuns.

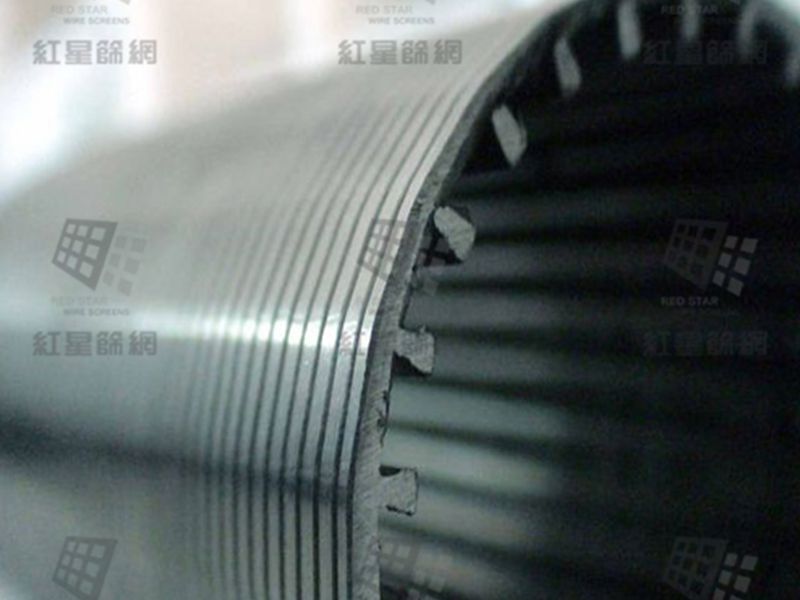

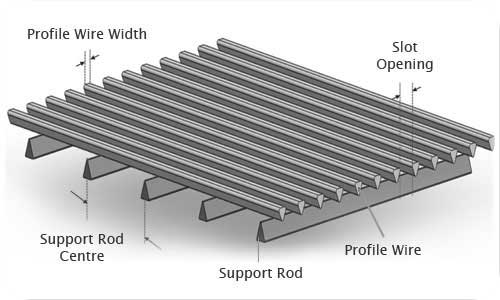

Wedge wire screens consist of profile wire and support rods with the materials of galvanized steel, low carbon steel and stainless steel 304, 316.

According to the wedge wire screen catalogue – ferrite: AISI 430 (1.4016); austenite: AISI 304 (1.4301), AISI 304L (1.4307), AISI 202 (1.473), AISI 316 (1.4401), AISI 316L (1.4404), AISI 317LN (1.4439), AISI 904L (1.4539), AISI 321 (1.4541), AISI 316Ti (1.4571), Duplex: 329 LN (1.4462), 439 (1.4410); Special: 2.4360, 2.4610, 2.4816

Slot

Standard from 0,02 mm. Smaller on available on customer’s request.

Support wire

According to the wedge wire screen catalogue – type I*: 10x2, 10x3, 12x3, 18x2; type Q*: Q35, Q55

Wire

According to the wedge wire screen catalogue – standard wire Sb* type: 12Sb, 18Sb, 22Sb, 28Sb, 34Sb, 42Sb, 60 Sb, 70 Sb; SbA50; special wires*: Sbb34, Sbb38, Sbb42, Sbb48, Sbb50; 2,4x5; 3x6,5

Dimensions

Ø 100-630 mm, max.: 6000 mm

Increased efficiency

a)Capability to withstand heavy loads

b)High open area

c)No clogging

d)Perfectly smooth and flat surface

e)High precision of execution

f)Increased capacity and more precise separation, dewatering and filtration

g)Self-cleaning effect

h)Low pressure loss

>> High open area and strength parameter

a)Proper size of profile wire

b)Proper size of structural support wire

c)Profiles shape of working wires

>> Increased economical effectiveness, lower cost

a)Higher efficiency

b)Permanence of exploited resources

c)Ease of installation and reduced maintenance cost

>> Extended lifetime

a)Slot does not change during abrasive operation on the screen surface

Perfect package.

All our wedge wire screen are perfect packed. The common packages of wedge wire screen are waterproof papers and wooden case. The waterproof paper or plastic film can protect the wedge wire screen from moisture and sea waters. The wooden case or pallet can prevent the wedge wire screen from impact.

Short delivery time.

All the products are produced on the automatic equipment, which can reduce production time. The skilled workers can reduce production time and reduce production losses. The convenient transport can ensure the goods can be transported to the port in a short time. Professional shipping agent can help to arrange the fastest shipping date to ensure the short shipping time.