Self Cleaning Screen

Self Cleaning Screen Mesh Has High Load Capacity, Self-Cleaning Ability

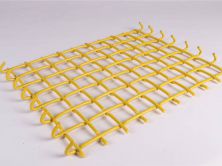

Self-cleaning screen media was initially engineered to resolve screen cloth blinding, clogging and pegging problems. The idea was to place crimped wires side by side on a flat surface, creating openings and then, in some way, holding them together over the support bars. This would allow the wires to be free to vibrate between the support bars, preventing blinding, clogging and pegging of the cloth. Initially, crimped longitudinal wires on self-cleaning cloth were held together over support bars with woven wire.

Nowadays, self-cleaning screen has became a screen with polyurethane strips to replace woven cross wires. The polyurethane strips lessens the vibration of the longitudinal wires over the support bars but does not stop it, consequently allowing vibration from hook to hook.

This product is not only a high-performance screen but also a problem solver. The independent vibrating wires helped produce more product compared to a woven wire cloth with the same opening (aperture) and wire diameter. This higher throughput would be a direct result of the higher vibration frequency of each independent wire of the screen cloth (calculated in hertz) compared to the shaker vibration (calculated in RPM), accelerating the stratification of the material bed. Another benefit that helped the throughput increase is that hybrid self-cleaning screen media offered a better open area percentage than woven wire screen media. Due to its flat surface (no knuckles), hybrid self-cleaning screen media can use a smaller wire diameter for the same aperture than woven wire and still lasts as long, resulting in a greater opening percentage.

We have various types meshes. You can choose the suitable one.

FEATURES & BENEFITS

Features

High screening efficiency

High gothrough rate

Less blinding, blocking or pegging

Less maintenance

Reduce the plugging

Various types of meshes.

Specification

Material: High carbon steel wire, spring steel wire, manganese steel and stainless steel wire.

Wire diameter:1.6–5 mm.

Mocular Self-cleaning screen available.

Edge:Hooked edge is available.

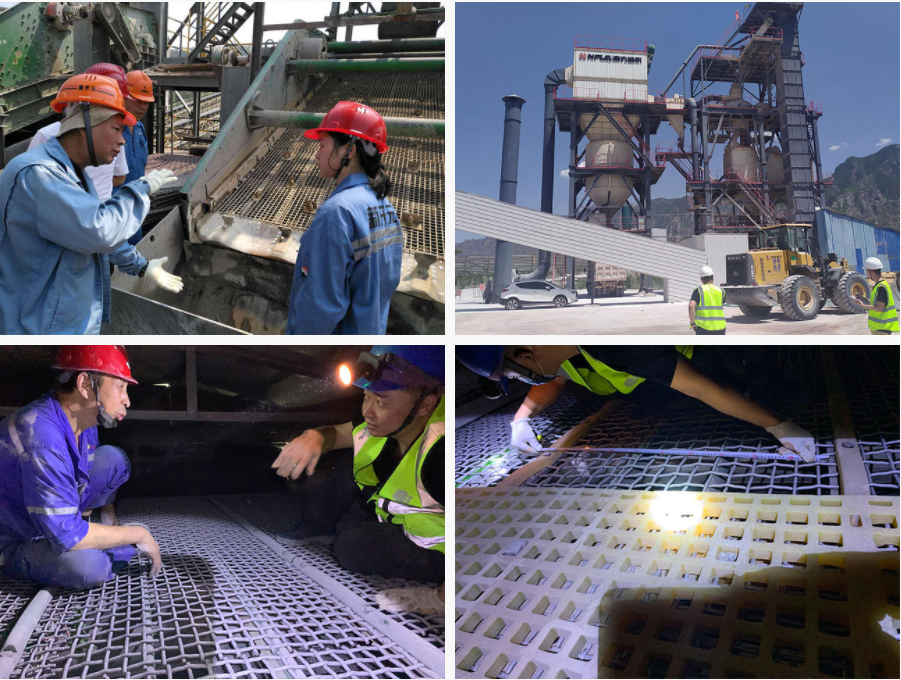

APPLICATIONS

Self cleaning screen mesh can filter the most wet materials in the following areas:

Mining industry. Quarry. Aggregate processing industry. Chemical industry. Sand and gravel industry.

Red Star premier manufacturer of aggregate, mining, quarry, industrial, and architectural screens with you to design, develop and implement a custom solution to fit your unique project.

Add: Qianpu Developing Zone,Anping, Hebei Pro. China 053600

Tel: +86-18832853977

Fax: +86-318-7525989

Email: rsanping@redstarfactory.com

Polyurethane Self-cleaning Screen

Inquire

Polyurethane Self-cleaning Screen

Inquire

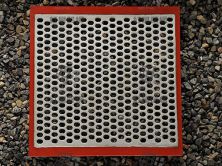

Self-cleaning Modular Screen Panels

Inquire

Self-cleaning Modular Screen Panels

Inquire

PU Self -cleaning Screen

Inquire

PU Self -cleaning Screen

Inquire

Self-cleaning Metal Mesh

Inquire

Self-cleaning Metal Mesh

Inquire

PU Modular Screen Panels

Inquire

PU Modular Screen Panels

Inquire

Modular Screen Panels

Inquire

Modular Screen Panels

Inquire

Rectangular Woven Screen

Inquire

Rectangular Woven Screen

Inquire

Double Crimp Screen

Inquire

Double Crimp Screen

Inquire

Lock Crimp Screen

Inquire

Lock Crimp Screen

Inquire

Twin Wire Woven Wire Screen

Inquire

Twin Wire Woven Wire Screen

Inquire

Flat Top Screen

Inquire

Flat Top Screen

Inquire

Slot Screen

Inquire

Slot Screen

Inquire

Cross Tension Mats

Inquire

Cross Tension Mats

Inquire

Stainless Steel Wedge Wire Screen

Inquire

Stainless Steel Wedge Wire Screen

Inquire

Polyurethane Tufflex Screen

Inquire

Polyurethane Tufflex Screen

Inquire

Flip Flow Screen

Inquire

Flip Flow Screen

Inquire

Polyurethane Fine Screen

Inquire

Polyurethane Fine Screen

Inquire

Stainless Steel Shale Shaker Screen

Inquire

Stainless Steel Shale Shaker Screen

Inquire

Stainless Steel Composite Screen

Inquire

Stainless Steel Composite Screen

Inquire

Polyurethane Bolt

Inquire

Polyurethane Bolt

Inquire

Polyurethane Support Bar

Inquire

Polyurethane Support Bar

Inquire

Polyurethane Hold Down Bar

Inquire

Polyurethane Hold Down Bar

Inquire

Polyurethane Rail Seat

Inquire

Polyurethane Rail Seat

Inquire

Polyurethane Liner Plate

Inquire

Polyurethane Liner Plate

Inquire

Polyurethane Crash Pad

Inquire

Polyurethane Crash Pad

Inquire

Polyurethane Water Jet

Inquire

Polyurethane Water Jet

Inquire

Scrapper

Inquire

Scrapper

Inquire

Square Wire Screen

Inquire

Square Wire Screen

Inquire

Shale Shaker Screen Cloth

Inquire

Shale Shaker Screen Cloth

Inquire

Slot And Rectangular Wire Screen

Inquire

Slot And Rectangular Wire Screen

Inquire

Polyurethane Rollers

Inquire

Polyurethane Rollers

Inquire

Stainless/Carbon steel woven wire screen

Inquire

Stainless/Carbon steel woven wire screen

Inquire

Stainless/Carbon Steel Punch Plate Screen

Inquire

Stainless/Carbon Steel Punch Plate Screen

Inquire

PU Hybrid Screen Panels

Inquire

PU Hybrid Screen Panels

Inquire

Stainless/Carbon Steel Finger Screen

Inquire

Stainless/Carbon Steel Finger Screen

Inquire

Polyurethane Screening Accessories

Inquire

Polyurethane Screening Accessories

Inquire

Polyurethane Flip-Flow Vibrating Screens

Inquire

Polyurethane Flip-Flow Vibrating Screens

Inquire

Polyurethane Mining Tires

Inquire

Polyurethane Mining Tires

Inquire

Metal Punch Plate Screening

Inquire

Metal Punch Plate Screening

Inquire

Wedge Wire Screen

Inquire

Wedge Wire Screen

Inquire

Stainless Steel Double Crimp Screen

Inquire

Stainless Steel Double Crimp Screen

Inquire

Stainless Steel Flat Top Screen

Inquire

Stainless Steel Flat Top Screen

Inquire

Stainless Steel Rectangular Screen

Inquire

Stainless Steel Rectangular Screen

Inquire

QUICK LINKS

Redstar Wire Mesh MFG CO., LTD.

Qianpu Developing Zone, Anping, Hebei Pro. China 053600

Copyright © 2019 Hebei Red Star IMP.&EXP.COMPANY XML 丨 HTML

PRIVACY POLICY