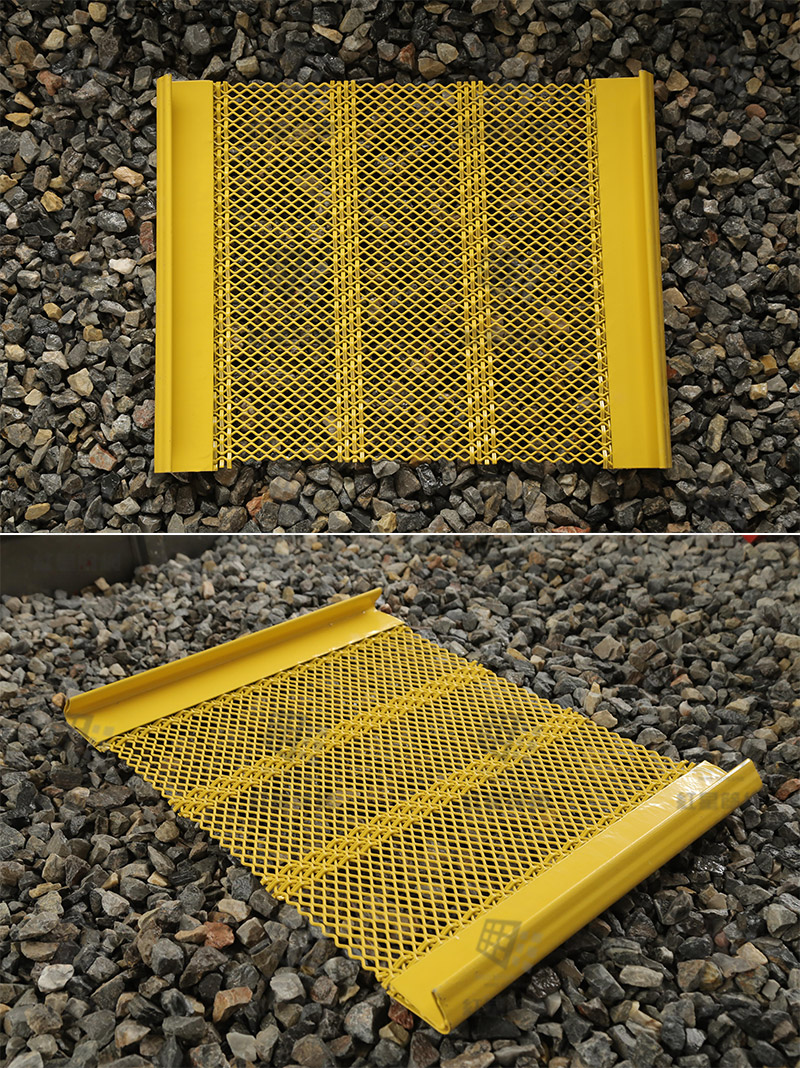

The per-undulated wire, placed one next to the other form the aperture. this way the materials follow the direction for one of the diagonals of the aperture.as the wirers are independent,the collisions pro-duced by the products cause the differences in the vibration the prevent the clogging of the fine products between the wires. this type of mesh is the most used to keep in place the aperture of these meshes . the wired ones are used when the classification is done at higher temperatures than 80 like at the asphalt mixture plants.

These Screens are made of horizontally crimped round wires, with 6 interwoven cross weaves wires.

Material: High tensile steelwire , stainless steel wire

Characteristics:

high performance and excellent self cleaning,long wear-life

More opening area

30% more capacity than woven wire

Eliminates blinding and plugging

3 times longer wear life time than woven wire

Minimizes down time cleaning and unclogging

Maximizes throughput

Application:

sand and gravel industry,

ore preparation plants,

mining industry

For damp, sticky, hard-to-screen material